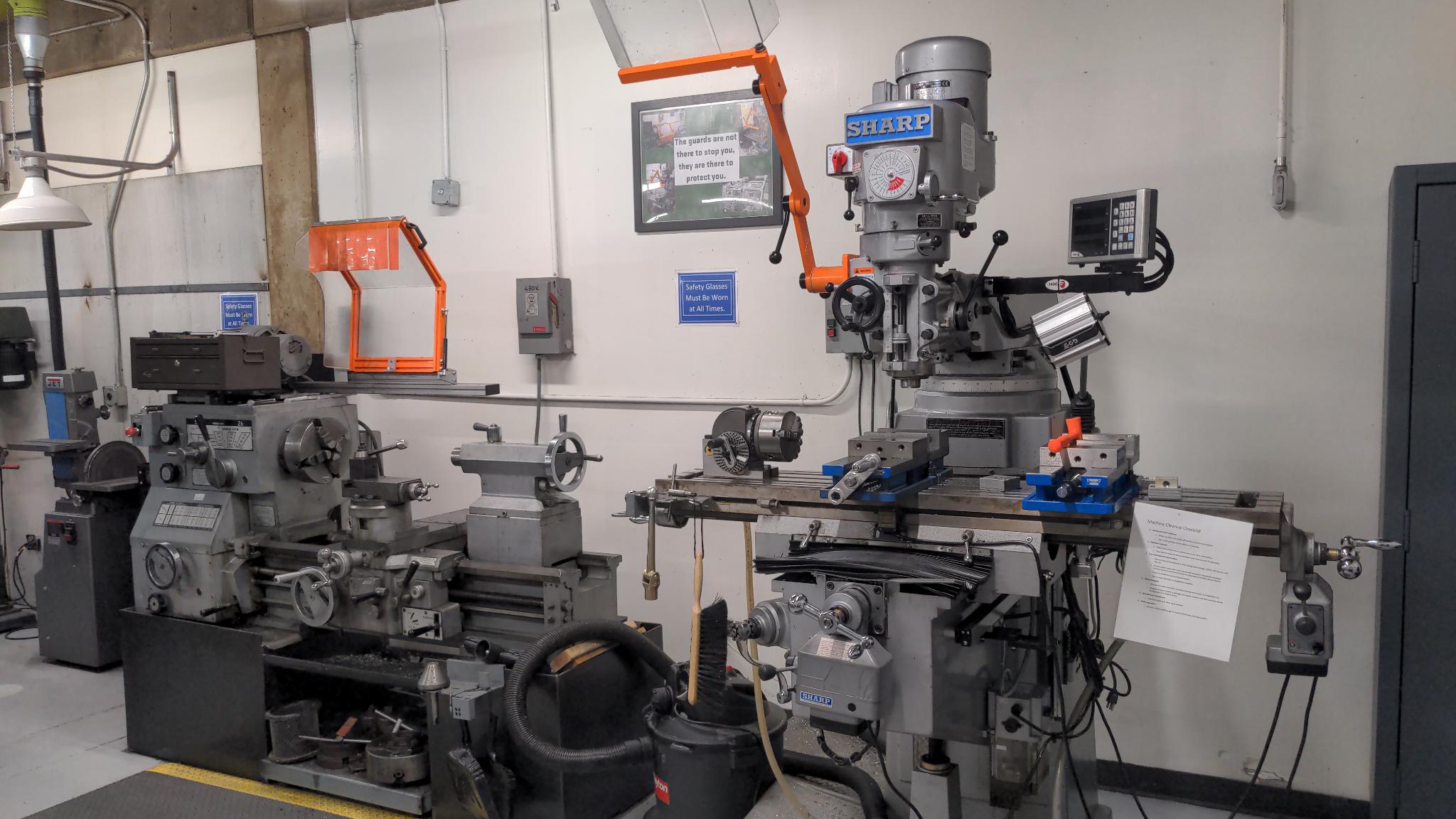

Learning How to Build Things in UVU's Machine Shop

Date: 2025-02-01

In my last semester at UVU, I took 3 machining and welding classes at UVU for fun. Here are the 3 most impressive things I built.

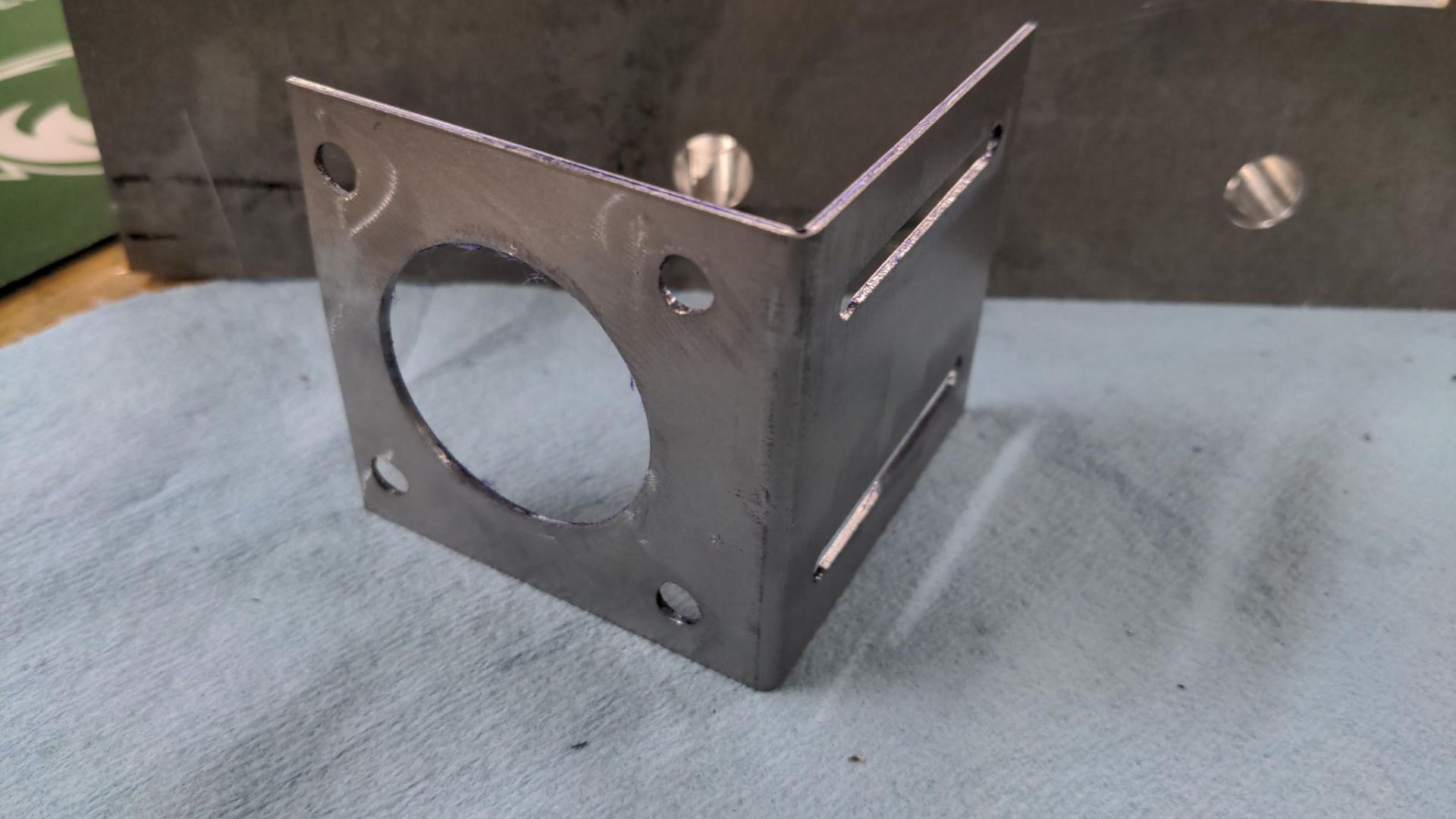

Nema 23 stepper motor mount

The first thing our class built was a steel motor mount.

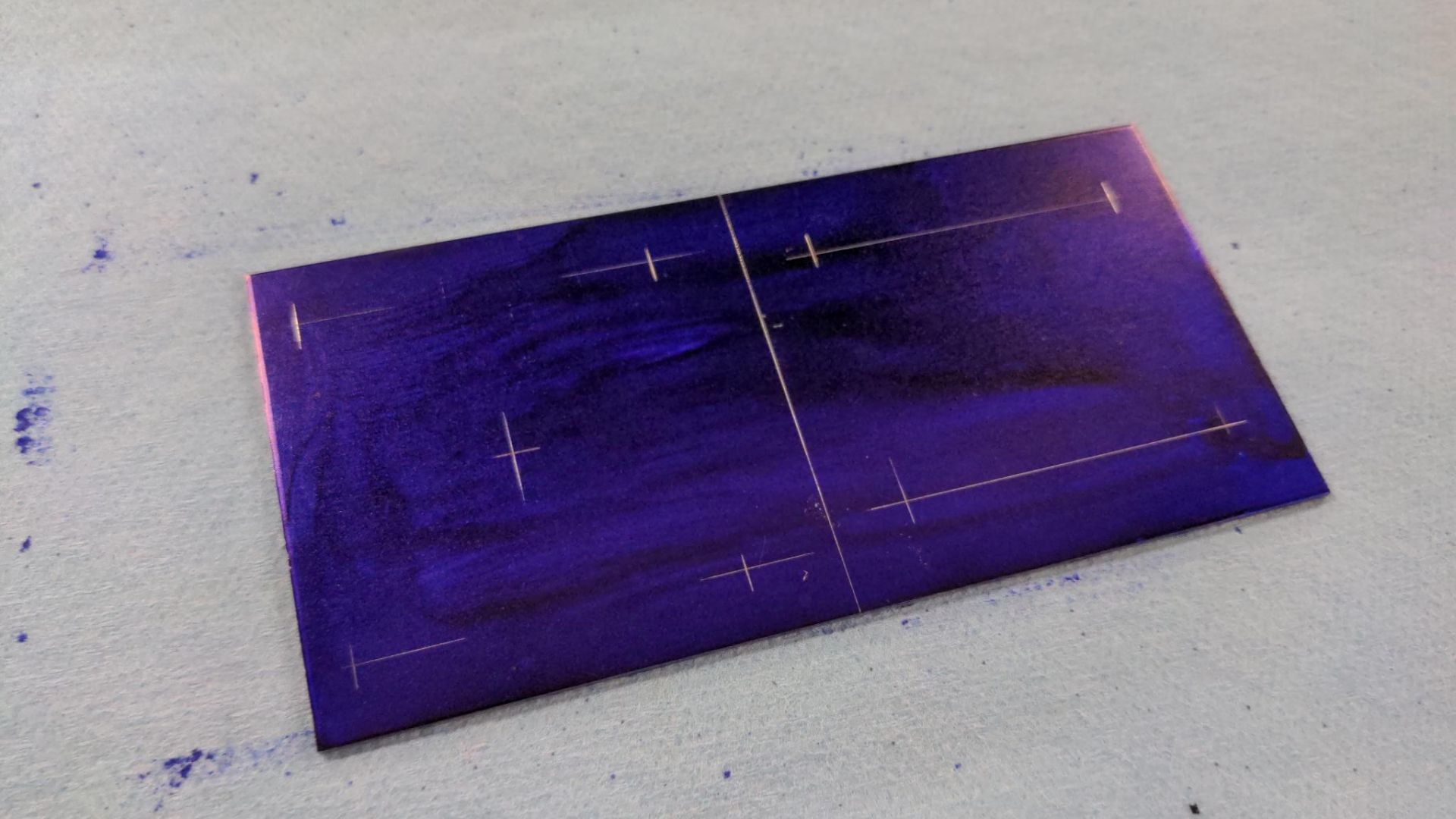

We atarted by painting the part with Dykem dye and marking measurements.

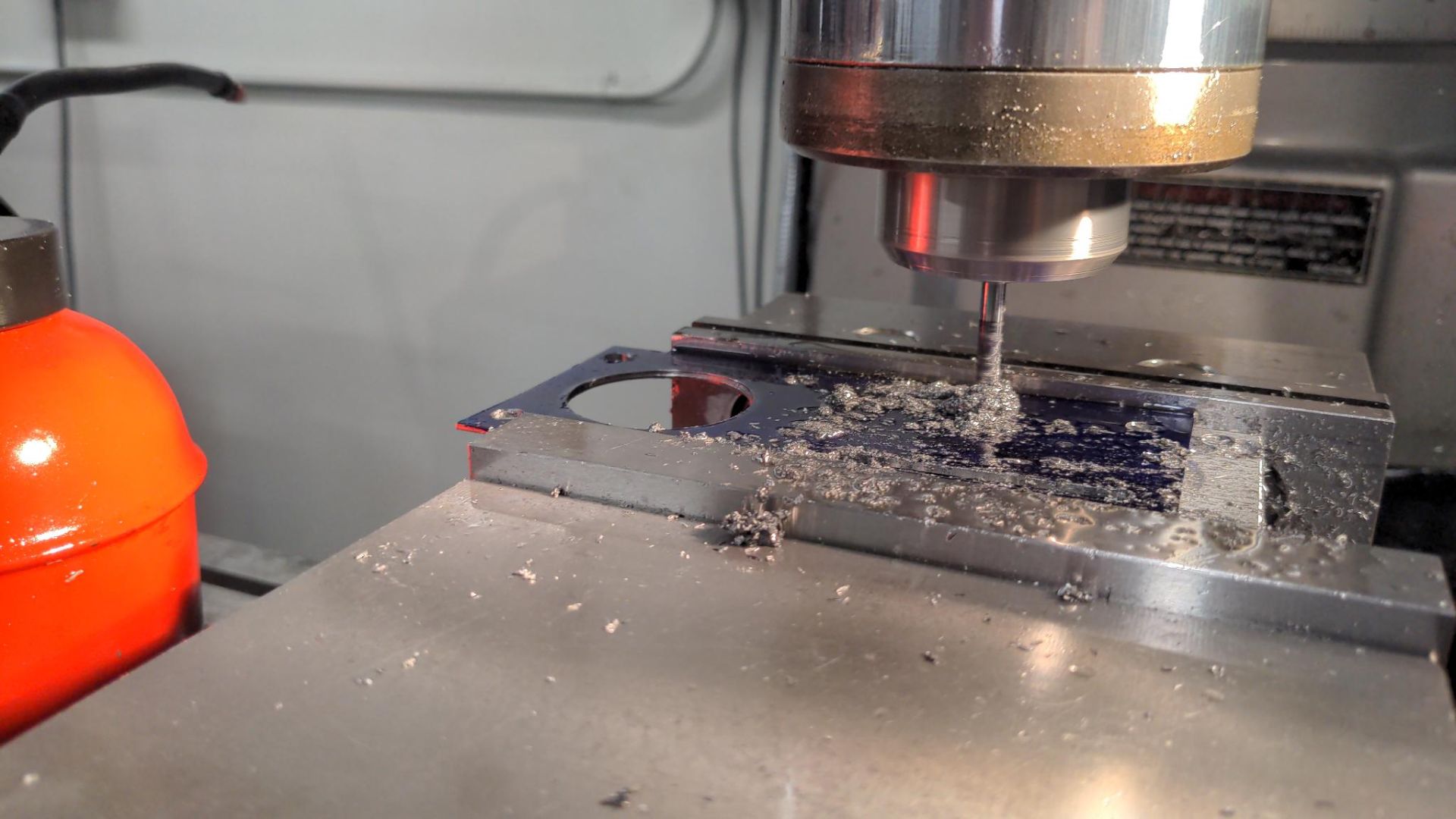

Then, we manually drilled and machined the Slots.

Lastly, we sanded the mount.

And bent it into shape.

It was fun actually using the mill after 2 weeks of classwork! With it being my first time machining anything, I made some mistakes. Most notably, some of the holes are a little off from the measurement. So next time, I'll spend more time making sure I drill in the exact correct spot.

Sand cast aluminum

Machining a bike tool

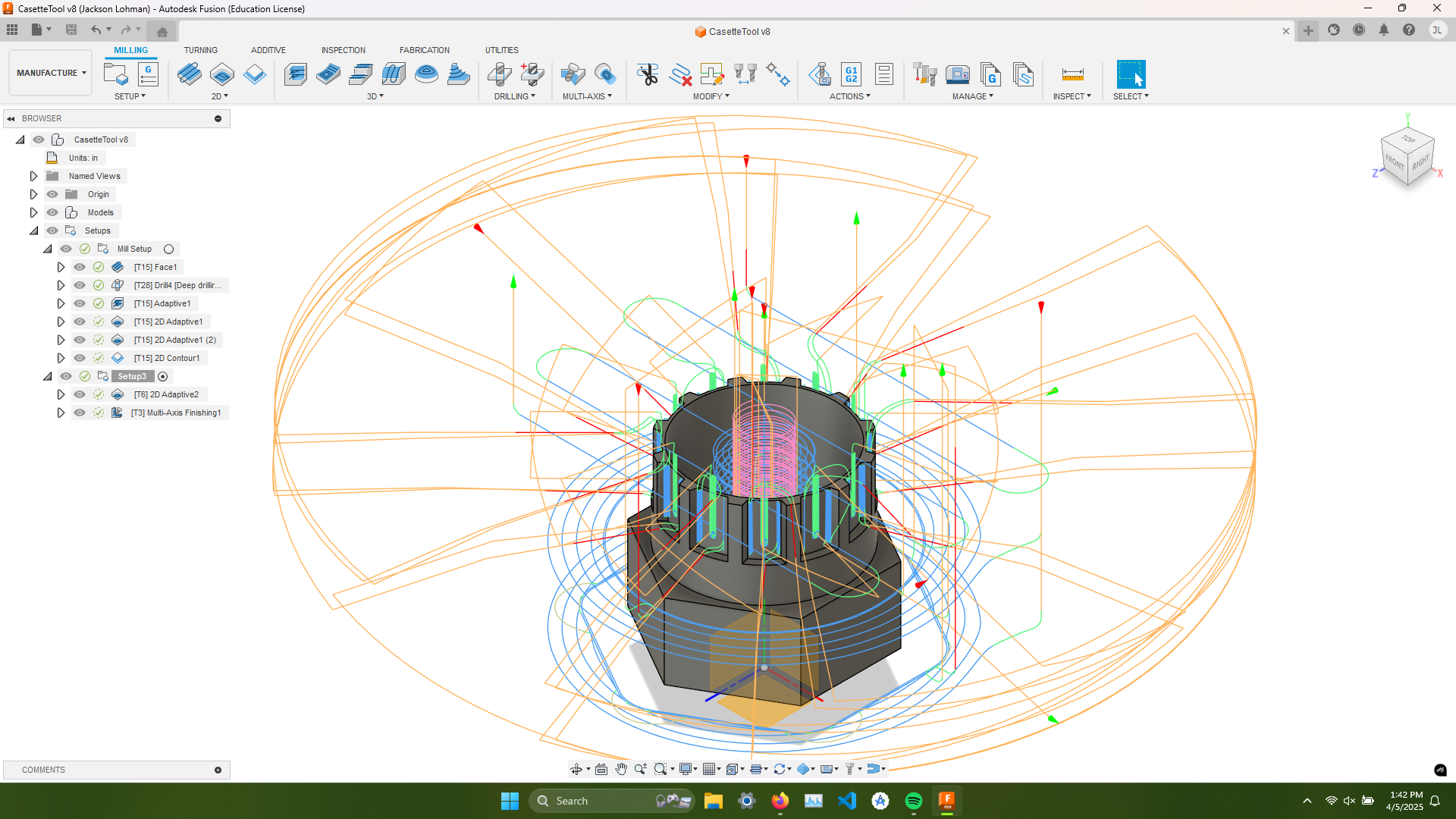

In the machining class they typical final is a machined aluminum keychain. Instead of that, I got permission to machine a much more complicated stainless steel bike cassette tool. Here is the Fusion model complete with tool paths.

And here is the progress so far: (Getting the 4th axis working on a CNC mill is difficult)

The blue part of the tool on the left is built for bike thru axels. I am building the same tool but without the blue part so it works with Quick Release axels.